The production line is composed of twin screw extruder, double layer extruder head, molding machine, molding module, cutting machine and flaring machine. Technical capability,Below and HDPE pipe fitting suppliers together to understand.

1. Double extruder head

The nose adopts advanced technology, optimized design and processing by Third Base Company. The main material of the nose is 40Cr, which is treated with tempering and nitriding. The total heating power is 39KW. Because the head works continuously under extreme pressure and elevated temperature, the material properties of the head parts are extremely strong. The material selection of the Third Base company has reached the requirements of extreme hardness, corrosion resistance, deformation resistance and extreme durability. At the same time, the head has met the optimal design of uniform material flow, no flow resistance and reasonable compression ratio distribution. To meet the above performance requirements, all the materials of the head parts are made of high-quality structural steel, and the parts are processed by CNC. The fire parts are processed by heat treatment numerous times, and the hardness is increased by heat treatment.

2. Molding machine

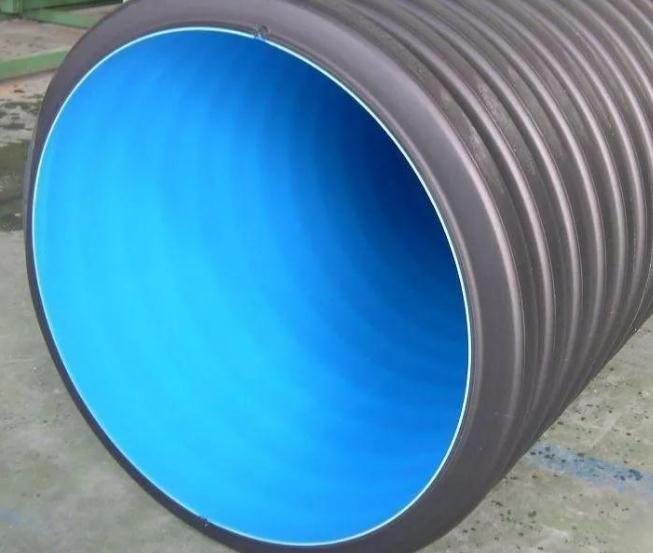

HDPE tube molding machine adopts closed molding module chain, open design. The forming module made of special aluminum alloy is equipped with upper and lower rack and driven by upper and lower gear. The specially designed guide track makes each pair of forming modules accurately aligned in the forming channel. The molding module is aluminum alloy mounted on the conveyor base with a quick removal tension bolt, which makes it easy to alter production specifications. The cooling method adopts external cooling. When the molding module moves in the molding channel and the return channel, the cooling water is continuously pumped into the module to make it have excellent heat transfer to ensure strong extrusion capacity.

The speed of the molding machine can reach 0.5In ~ 4m/min, and the production efficiency is elevated. The main motor adopts DC speed regulating motor, using the UK European 591 digital DC governor, large traction, smooth speed regulating, wide range of speed adjustment. The device has the function of 32 power failure return, using the charging device imported from the United States, the battery has the function of maintenance free, the energy to ensure that the 32 units can still be returned when the sudden power failure, so that the module and the nose water jacket off. The rack can be single moving and linkage.

3. Planet cutting machine

It is composed of guide rail fixed frame, mobile frame and rotary assembly, clamping mechanism, chip absorption mechanism and so on. Cutting saw adopts hydraulic feed system, which can achieve smooth and high speed cutting. The clamping mechanism is respectively fixed at both ends of the moving frame. Each clamping mechanism is composed of a cylinder and six clamping jaws. Under the action of the cylinder, the six clamping jaws clamp the pipe at the same time to ensure that the moving frame transfer speed is synchronized with the pipe production speed. The six claws are equipped with a special adjustable positioning device designed for bellows cutting to ensure the accuracy of each cutting position. The equipment is provided with two groups of cutting-absorbing mechanisms, one group is installed on the cutting-absorbing cover of the cutting tool, and the remaining group is installed on the large hopper at the bottom of the inner cavity of the mobile frame. The pipe chip is sucked off, effectively preventing the pollution of the working environment. It can realize automatic pipe cutting in line.